Plywood

Plywood is an engineered and manufactured sheet of wood paneling composed of many thin layers (plies) of wood, glued and bonded together. The finished result is an evenly textured panel of wood with criss-crossing grains that provide strength and stability. Here we’ll highlight 7 plywood types, and discuss their benefits and uses.

Sanded AC Plywood

Sanded AC Plywood is specifically made with a knot-free face, which is sanded to a smooth, even surface. It can be used for walls, furniture, cabinets, bars and islands, shelving, and more. An elegant choice in plywoods, Sanded AC is a great choice for elevating your project’s aesthetic value, and applications where a smooth surface is important.

Pressure Treated Plywood

Pressure treated plywood uses pinewood for its veneer and is more forgiving than other options when it comes to bending. Perhaps its most important feature, however, is that it is pressure treated, protecting it from moisture and decay. Pressure treated plywood is also resilient against termite and insect damage.

Pine CD Plywood

Plywood that is graded Pine CD is used for sheathing building surfaces that will end up being covered by a different material. It is not sanded or smooth.

Fir CD Plywood

Fir CD Plywood is another great option for interior sheathing, roofing, and framing applications, providing a stronger alternative than its pine counterpart.

Hardwood Plywood

Hardwood Plywood is a layered plywood panel with an outer veneer of hardwood, such as oak or birch. Oak Plywood is a great substitute for those who want oak cabinets or furniture of oak finishes without the price tag of traditional oak lumber. It is easy to work with and easy on the wallet. Oak Plywood is available in varying thicknesses and its veneer is typically graded very well. Birch Plywood is a hardwood plywood, renowned for its smooth finish, aesthetic, and ease of installation. The face veneer is made of birch. Birch Plywood is a great option for cabinets and furniture.

Underlayment Plywood

Not to be confused with subflooring, underlayment plywood is typically applied on top of sub flooring, and underneath carpet, vinyl flooring, tile, and many resilient floorings.

Reversible Beadboard Plywood

Used primarily for its aesthetic quality, Reversible Beadboard Plywood is a smooth paneling option. This is a great choice for a beaded, wainscot look.

Benefits of Plywood

Plywood panels have some distinct advantages that set them apart from solid woods:

- Strength – Because of plywood’s pattern of alternating grains, the board’s strength is distributed evenly across the whole piece.

- Durability – Plywood can withstand heavy impacts and heavy loads.

- Weight – For as strong as it is, and as big as the boards can be cut, plywood is surprisingly light and easy to transport. For projects that require overhead construction, plywood paneling offers a greater ease in installation.

Common Projects Using Plywood

Because of its strength, durability, and reasonable price, Plywood can be used in many different indoor and outdoor applications.

- Exterior wall sheathing – Perhaps the most common use of plywood you may see is for exterior wall sheathing. When the panels are fastened together, they help prevent vertical and horizontal shifting, stand up to high winds, and can cover a wide area.

- Furniture – Plywood’s versatility enables it to be used for just about any indoor furniture project you can think of from chairs and tables to dressers and bed frames. It takes wear and tear better than many other wood options, yet is light enough to easily move around the home or from one location to another.

- Cabinets – Its lighter weight and strength makes plywood a wonderful choice for kitchen cabinets. Plywood will hold strong to the backside against the wall as well as the weight of the dishes and glasses you put inside. A high-quality hard plywood also provides a beautiful look, should you wish to keep the natural look of the wood showing.

Handling, Safety Tips, and Maintenance

- Sawdust & debris – Clean all remnants of your construction and dispose of them properly. For any leftover pieces of raw lumber, contact a wood-waste dealer or your local waste disposal provider for details on recycling or repurposing.

- Protective gear – Wear a dust mask and goggles when cutting any lumber.

- Painting & staining – When painting plywood, latex paint and semi-gloss paint are good choices. However, before you begin adding your favorite colors, you may need to fill in any irregularities with wood filler. Once that dries, apply joint compound uniformly to the entire surface that will be painted. This will help smooth plywood panel edges and cover rough, exposed surfaces. You will then need to sand the project down for more smoothness, then add primer, then finally paint.

Plywood Dimensions and Current Stock

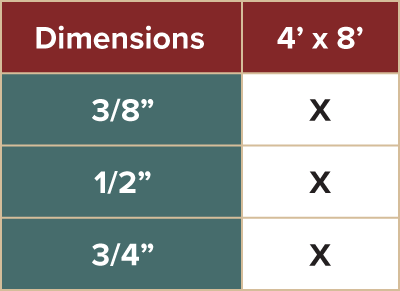

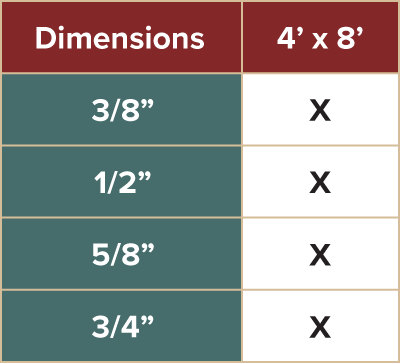

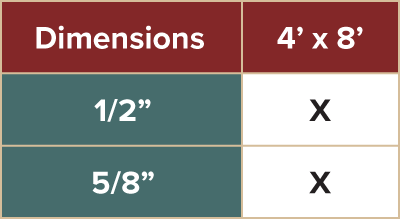

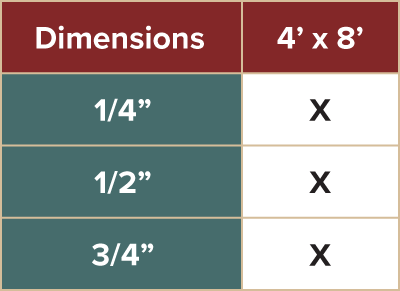

View the charts below to see what we currently have in stock:

Sanded AC

Pine CD

Fir CD

Hardwood (Oak and Birch)

Underlayment

Reversible Beadboard